Dam displacement monitoring is a critical link, and monitoring methods are mainly divided into two categories: manual inspection and instrument monitoring. Manual inspection can identify intuitive problems through daily, regular, and special-period checks, but it has shortcomings such as strong subjectivity and low efficiency. Although instrument monitoring is accurate and efficient, it is limited to monitoring of typical sections and cannot easily detect non-representative potential issues. Therefore, it is necessary to organically combine manual inspection with instrument monitoring, and reliable-performance dam displacement monitoring equipment serves as an important support for the coordinated advancement of the two.

The installation of dam displacement monitoring equipment requires comprehensive consideration of project scale, dam type characteristics, dam height and length, and the scope of impact downstream. The specific standards are as follows: For earth-rock dams with a height exceeding 30 meters or a significant downstream impact, and for concrete dams and masonry dams with a height exceeding 50 meters or a major downstream impact, surface deformation monitoring facilities must be installed; for other small reservoirs, monitoring facilities must be installed in accordance with specification requirements and combined with actual project conditions to ensure full coverage of safety monitoring.

Different dam types have different focuses in displacement monitoring, and monitoring equipment must be adapted to meet these needs. During the operation of earth-rock dams, vertical displacement has a more obvious impact on stability, so surface vertical displacement monitoring is the main focus. The selected equipment must ensure the accuracy and stability of vertical displacement data collection and be able to monitor subtle changes in the vertical direction in real time. Due to their structural characteristics, concrete dams and masonry dams are prone to safety hazards caused by horizontal displacement, so surface horizontal displacement monitoring is the main focus. The supporting equipment must improve the sensitivity and reliability of horizontal displacement monitoring to detect abnormalities in horizontal displacement in a timely manner.

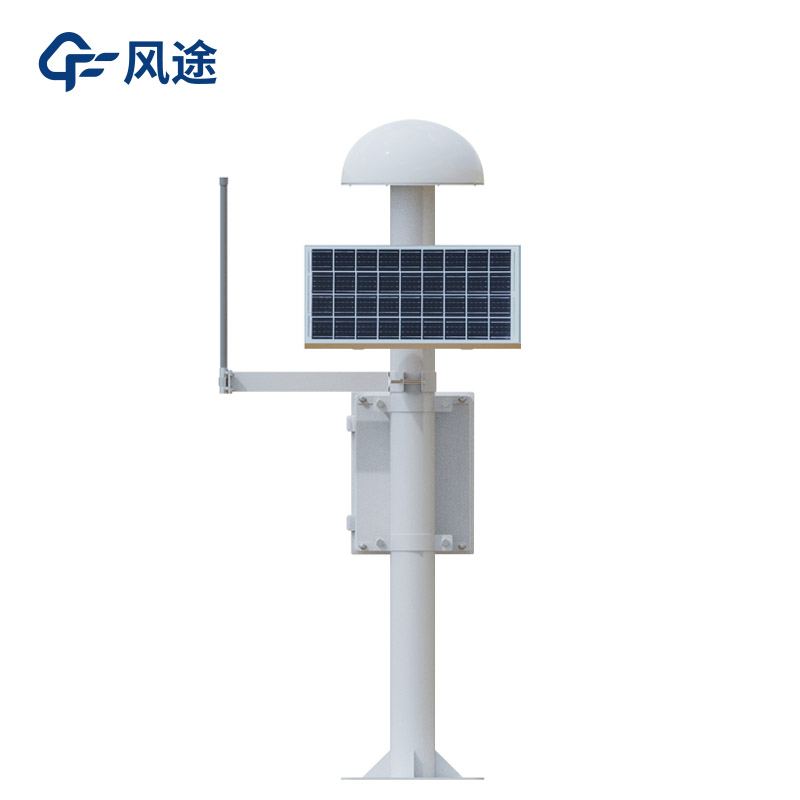

In actual monitoring, a single piece of equipment cannot meet the needs of comprehensive and accurate monitoring. Therefore, integrated monitoring systems that integrate multiple technologies have emerged. Such systems achieve functional complementarity by combining two or more types of equipment. For example, a certain integrated displacement monitoring system combines inclinometers (which accurately monitor vertical displacement) with positioning monitoring equipment based on GNSS monitoring stations. By virtue of the real-time dynamic positioning technology of GNSS monitoring stations, it can efficiently record displacement changes of the dam in the horizontal direction, and match inclinometers to obtain vertical displacement data, thereby realizing simultaneous monitoring of the dam’s vertical and horizontal displacements. This combined monitoring method not only expands the monitoring range, but also further improves the comprehensiveness and accuracy of data by relying on the high-precision advantage of GNSS monitoring stations. It provides reliable data support for dam safety assessment and ensures the safe and stable operation of the dam.

Article address:https://www.sqqx.net/en/news/734.html

+86 15898932201

+86 15898932201