Automated monitoring of settlement and deformation, based on differential RTK technology, enables continuous high-precision measurement of settlement and horizontal displacement of engineering structures. This system achieves millimeter-level deformation monitoring and is widely used in engineering safety fields such as dam safety monitoring, bridge health monitoring, and geological disaster landslide early warning.

Automated settlement deformation monitoring is a key technology for ensuring the long-term safety and stable operation of major infrastructure and geotechnical engineering projects. Traditional manual monitoring methods suffer from limitations such as low efficiency, long cycles, discrete data, and the inability to provide real-time warnings. Automated monitoring systems, by integrating high-precision sensors, automatic data acquisition, and remote transmission technologies, achieve continuous, real-time observation of structural deformation 24/7, significantly improving the timeliness and reliability of safety monitoring.

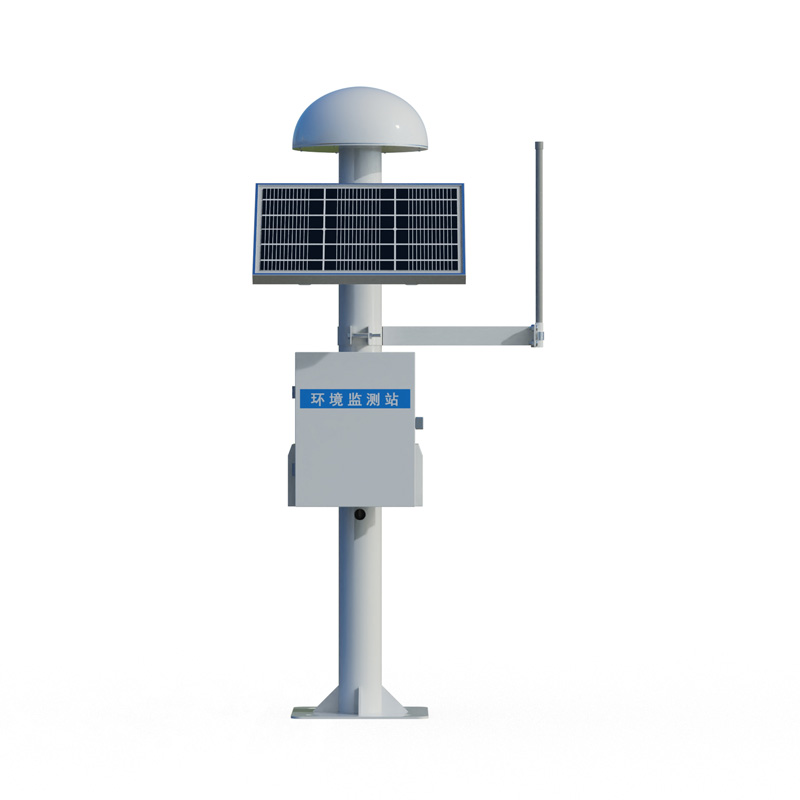

The core technology of this system is differential RTK measurement technology. RTK, or Real-Time Kinematic carrier phase differential technology, uses a base station and monitoring stations to receive satellite signals. The base station uses its known coordinates to calculate error correction information and transmits it to the monitoring stations in real time. The monitoring stations use this correction information to process their received signals, thereby obtaining centimeter-level or even millimeter-level planar and elevation positioning accuracy under dynamic conditions. For settlement deformation monitoring, the system typically deploys multiple integrated monitoring terminals as monitoring stations and establishes a base station in a stable area, forming a complete monitoring network.

A complete Automated monitoring of settlement and deformation system usually consists of three parts. The first part is the sensor and data acquisition unit, including high-precision GNSS receiver antennas and main units, which are fixedly installed at the monitoring points and are responsible for continuously capturing raw satellite observation data. The second part is the data transmission unit, which uses wired fiber optic or wireless communication methods such as 4G/5G to transmit data from each monitoring point and base station to the monitoring center in real time. The third part is the data processing, analysis, and management platform. This platform software receives the data, performs automated processing and adjustment, displays the three-dimensional displacement changes of each monitoring point in real time, and generates change curves and reports. The platform can set multi-level deformation warning thresholds; once the displacement exceeds the set range, the system immediately notifies management personnel via SMS, email, or platform alerts.

In practical engineering applications, this system demonstrates wide applicability. In the field of hydraulic engineering, it is deployed on dam surfaces and surrounding slopes to continuously monitor the settlement and horizontal displacement of the dam body during water storage, reservoir level changes, and long-term operation, providing core data for evaluating the structural performance of the dam. In transportation engineering, the system is used for bridge health monitoring, particularly in load testing of newly constructed bridges and long-term operation of existing bridges, accurately capturing pier settlement and bridge deck deformation. In the field of geological disaster prevention, this system is an effective tool for landslide early warning and monitoring. By deploying monitoring points on the landslide body, it can accurately capture millimeter-level creep displacement at different parts of the landslide body. Combined with analysis of triggering factors such as rainfall, it provides valuable time for landslide early warning and scientific prevention.

In summary, Automated monitoring of settlement and deformation, with its high precision, automation, and real-time capabilities, has become a standardized solution for modern engineering safety monitoring. It not only improves the efficiency and accuracy of monitoring work but also greatly enhances the proactive control capabilities of engineering structure safety risks through a real-time early warning mechanism, which is of great value in preventing disasters and ensuring the safety of people's lives and property. With the integration of the Internet of Things and artificial intelligence technologies, the data analysis and intelligent diagnostic capabilities of this system will be further enhanced.

Article address:https://www.sqqx.net/en/news/833.html

+86 15898932201

+86 15898932201